Time to Read 3 min

In embedded development this dilemma is encountered very often. Software development, especially user interface development must start, but:

- the target hardware does not exist yet

- the "machine" to be controlled is not ready either

- the user interface is unclear, many stakeholders are involved: marketing, management, software, hardware, mechanics, industrial design

Hardware and Mechanics out of the PC: Simulation

Instead of loosing a lot of time while waiting for the real world, electronics and mechanics can be simulated on a PC. In ASIC design, the approach is known as virtual platform or digital twin.

How does this work?

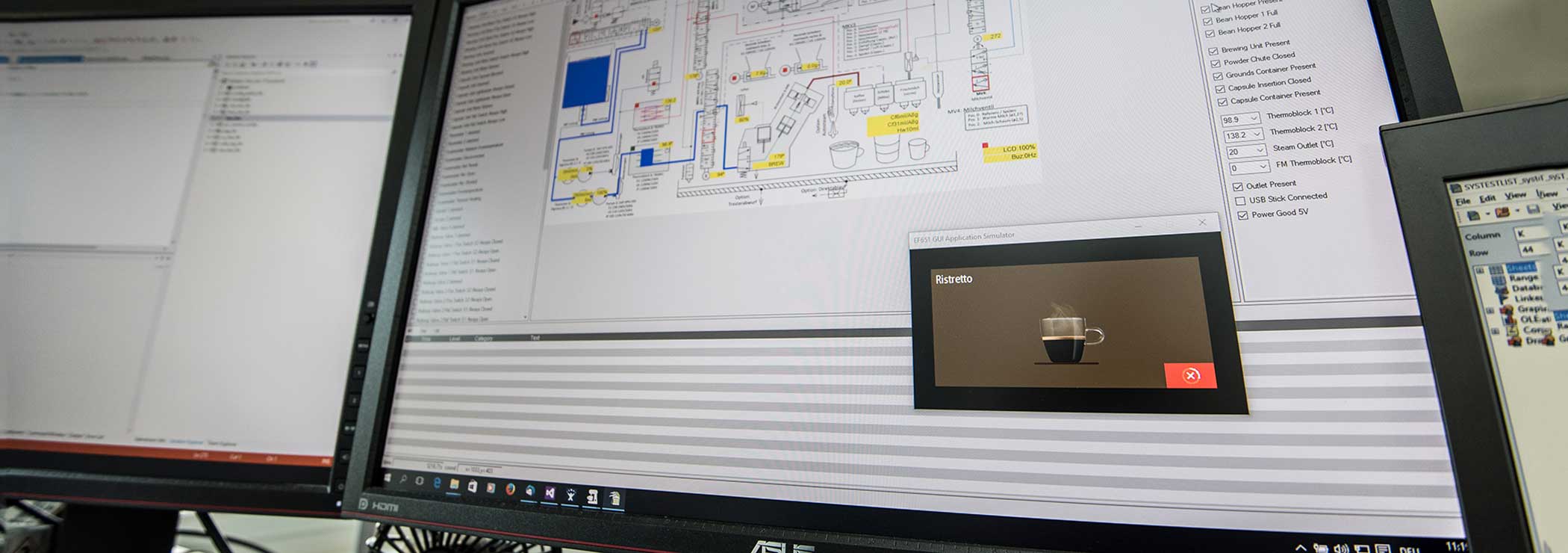

Solcept has developed a framework based on .NET/ C#/ managed C++. It can be used to simulate the operating system, drivers, hardware (down to the controller registers) and the underlying physics of the machine to be controlled on which the application is based.

The simulation is as accurate as needed and as simple as possible. This means the e.g. physical processes which are strongly influencing a controller design are modeled accurately. Other elements, e.g valves are simulated digitally (pass/ no pass).

Results

The following results were achieved in several projects using simulation/a digital twin:

- Integration of software and hardware is accomplished in one day (the drivers have been implemented and tested on evaluation-boards)

- Simpler testing leads to better test coverage and better software quality (e.g. because errors can be injected more easily, time in the simulation can be slowed and accelerated)

- The customer gets "exactly the user interface we wanted" (the PC simulation of the system can be evaluated by all stakeholders in an early stage which allows an iterative/ agile development style)

- The industrial designer sees the interplay of the mechanical part (e.g. buttons) of the user interface with its software part very early in the project

Advantages

The development engineers form a better understanding of the machine to be controlled, respectively its physics. In implementation and debugging PC development systems can be used which still offer more possibilities than most embedded tools.

A well programed simulator allows to extract logs, call chains and offers other functions like alterable execution speed to complete stop at any point. Together with complete reproducibility, which is seldom in the real world, embedded systems can be developed very efficiently.

During user interface development, all stakeholders can be brought on board at an early stage, since everyone can "play" with the graphical user interface (GUI) on their PC, but also with other elements such as buttons, indicator lamps and sounds.

Error conditions which are difficult or impossible (e.g. due to possible hazards) to create on a real machine, can be generated easily during tests. In addition automated tests can be conducted without modifications (e.g. test access ports, user interface exercising robots) of the target system, because it is simulated.

The supposed big disadvantage of course is the increased effort. According to our experience it is paid back over the duration of the project when more than three software test cycles are needed.

Alois Cavelti

Do you have additional questions? Do you have feedback or improvements? If so, email me or comment your thoughts below!

Author

is Dipl. Elektroingenieur FH , co-founder, deputy managing director and software developer. He is a specialist for architectures and software in C, C++ and C#. He is committed to maintainable architecture, security and clean code. For this he likes to look beyond the "embedded" edge of his nose into other areas of software development. He is interested in overall systems of any kind and their interrelationships. Alois manages a 5'000 m2 biodiversity island and brings nature, horses and humans in harmony. He loves good (movie) stories and good food.

No Comments